Tesla Model 3: Four Wheel Alignment (Check and Adjust)

Prepare for Adjustment

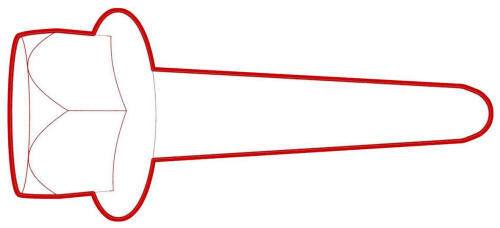

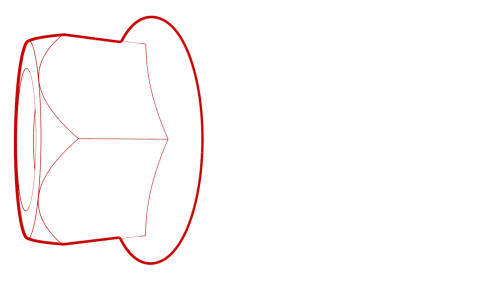

SPECIAL TOOLS

SEAT COVER (1096767-00-A)

Ballast Bag, 25lb (1145158-00-A)

CHASSIS HEIGHT MEASURING TOOL (1071271-00-A)

STEERING WHEEL LEVEL (1049463-00-A)

Prepare for Adjustment

- Make sure the tire pressures are to specification.

Note: Use the tire sticker values displayed on the door jam. If

unavailable, use these values:

-

18 inch wheels - 42 psi

-

19 inch wheels - 42 psi

- Make sure that the alignment rack slip/turn plates are locked.

- Disconnect the charging cable from the vehicle.

Warning: Do not attach the charging cable to the charge port while

the vehicle is on the rack.

- Drive the vehicle onto the alignment rack, and stop the vehicle

approximately 6 inches before the turn plates to allow for rolling

compensation.

- Shift into Park.

- Install wheel chocks.

- Install seat covers on the driver and front passenger seats.

- Set 150 pounds of ballast bags onto the driver seat, and 150 pounds of

ballast bags onto the front passenger seat.

- From outside of the vehicle, fasten the driver and front passenger seat

belts, and shift into Neutral.

- Pass a shop towel halfway through the both door strikers, and use a pen

to latch the doors.

- Raise the alignment rack to a working height and slightly lower to lock.

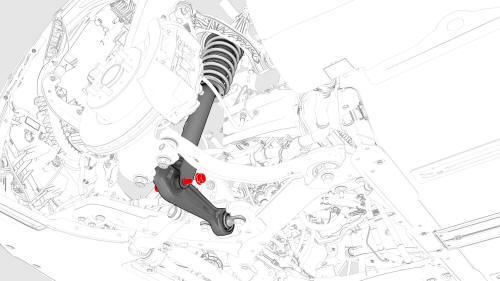

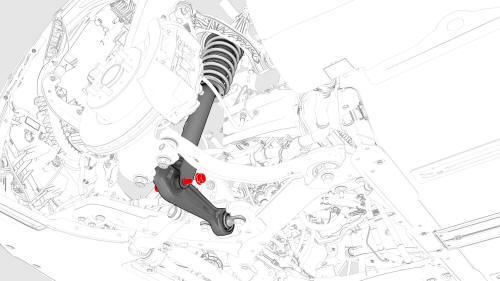

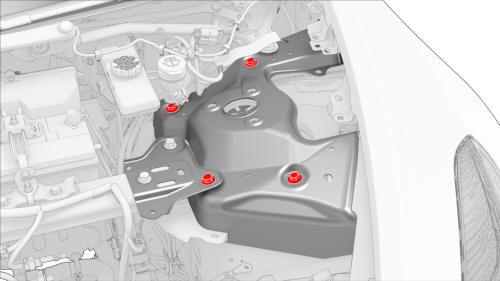

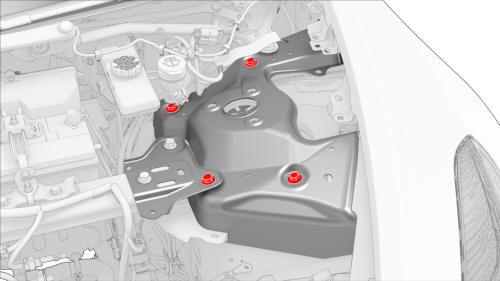

- Check the torque on the bolt and nut that attach LH and RH front lower

lateral links to the LH and RH strut assemblies.

Torque 106 Nm

Torque 106 Nm

Torque 106 Nm

Torque 106 Nm

- Install the alignment heads onto the wheels.

- Type the vehicle information into the alignment machine.

- Perform a rolling compensation and manually position the vehicle onto

the slip/turn plates.

- Remove the alignment slip/turn plate pins.

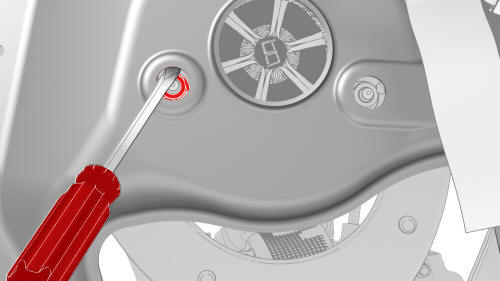

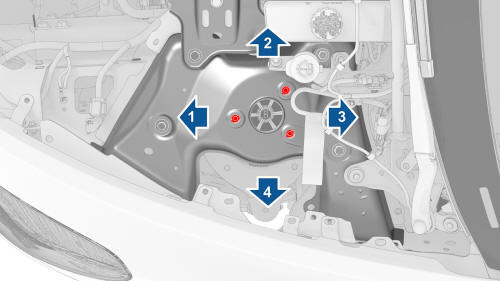

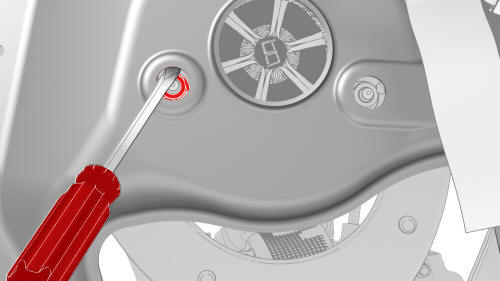

- Calibrate the ride height tool.

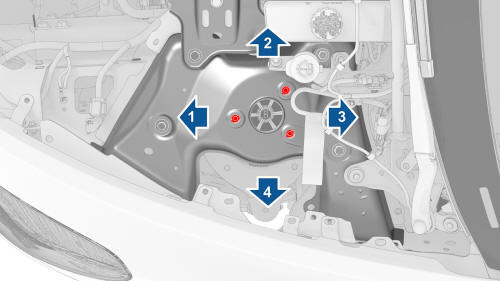

.jpg)

- Measure the ride height at 4 locations which are an additional 75 mm

towards the centerline from the vehicle lifting points.

- Move the front seats fore and aft to set the following ride heights:

- Performance front locations - 139mm +/- 3mm

- Non-performance front locations - 141mm +/- 5mm

- Performance rear locations - 146mm +/- 3mm

- Non-performance rear locations - 148mm +/- 5mm

- Install the brake pedal depressor and steering wheel bubble leveler.

- Perform a caster sweep, center and set the steering wheel using the

bubble leveler and steering wheel holder.

- Print the vehicle summary and identify which alignment parameters are

not within specifications.

Note: If the alignment parameters are within specifications, go to

step

2 of

Complete the Alignment.

- Raise the alignment rack to an overhead height and slightly lower to

lock.

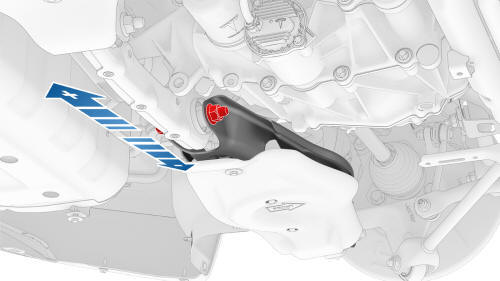

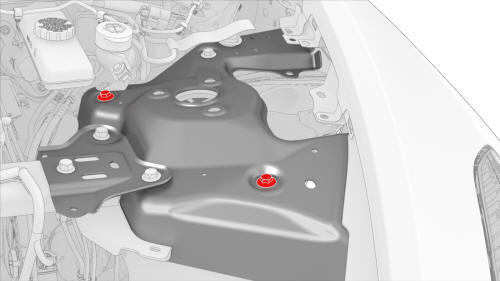

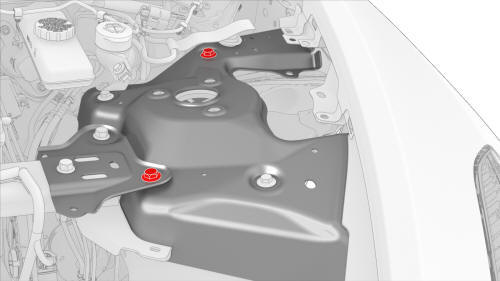

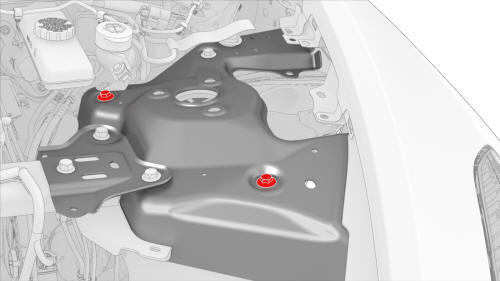

- Remove the mid aero shield panel. See

Panel - Aero Shield - Mid (Remove and Replace).

- Adjust the rear camber. See

Adjust Rear Camber.

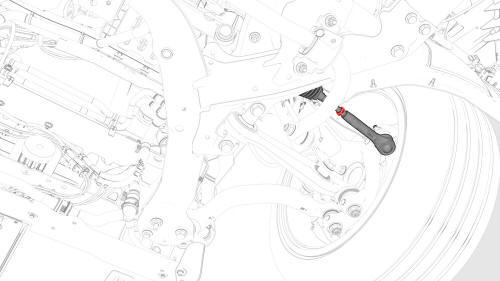

Adjust Rear Camber

- If the rear camber is within specification and does not require

adjustment, adjust the rear toe. See

Adjust Rear Toe.

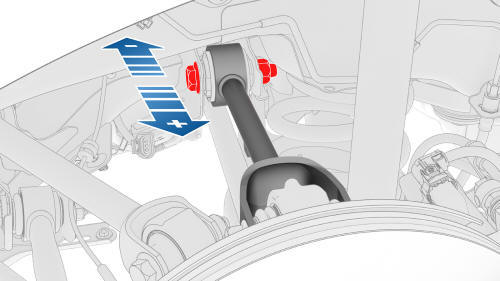

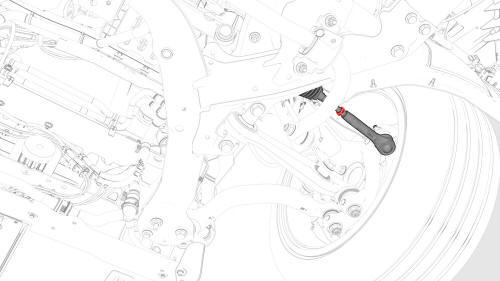

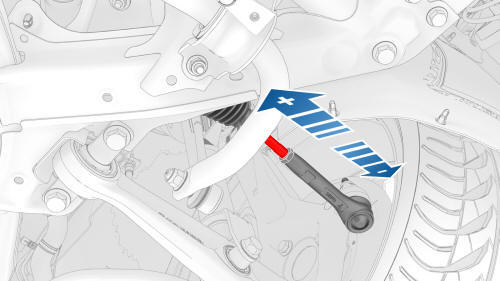

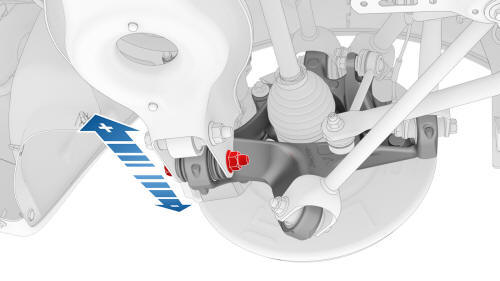

- Slightly loosen, but do not remove, the rear LH lower aft link to

knuckle bolt.

- Adjust the rear LH camber to -1.00º +/- 1.0º (+/- 0.80º split).

- Move the knuckle in toward the centerline to add positive camber.

- Move the knuckle out from the centerline to add negative camber.

- If the camber is correct, go to step

11.

- Slightly loosen, but do not remove, the rear LH lower aft link to

subframe bolt.

- Adjust the rear LH camber to -1.00º +/- 1.0º (+/- 0.80º split).

- Move the link in toward the centerline to add positive camber.

- Move the link out from the centerline to add negative camber.

- If the camber is correct, go to step

11.

- Slightly loosen, but do not remove, the rear LH upper aft link to

subframe bolt.

- Adjust the rear LH camber to -1.00º +/- 1.0º (+/- 0.80º split).

- To add positive camber, move the link out from the centerline.

- To add negative camber, move the link in toward the centerline.

- If the camber cannot be corrected, escalate a Toolbox session.

- Tighten the suspension bolts that were loosened.

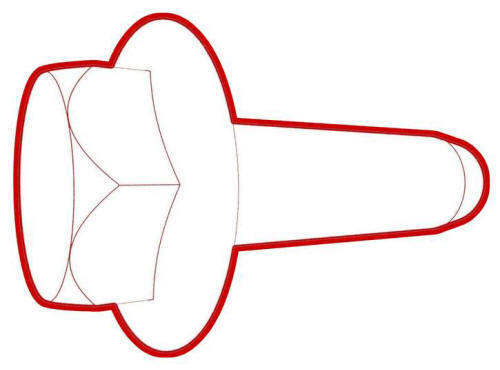

.png) Torque Lower Aft

Link to Knuckle Bolt 115Nm

Torque Lower Aft

Link to Knuckle Bolt 115Nm

.png) Torque Lower Aft

Link to Subframe Bolt 115 Nm

Torque Lower Aft

Link to Subframe Bolt 115 Nm

.png) Torque Upper

Aft Link to Subframe Bolt 134 Nm

Torque Upper

Aft Link to Subframe Bolt 134 Nm

- Perform step

2 through step

11 for the RH side of the vehicle if necessary.

- Adjust the rear toe. See

Adjust Rear Toe.

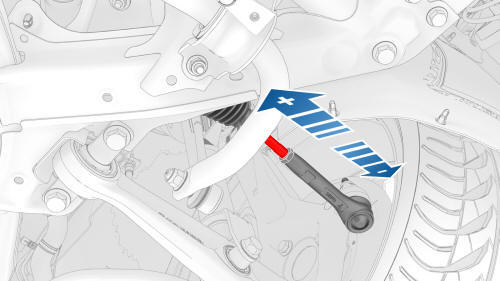

Adjust Rear Toe

- If the rear toe is within specification and does not require adjustment,

adjust the front camber and caster. See

Adjust Front Camber and Caster.

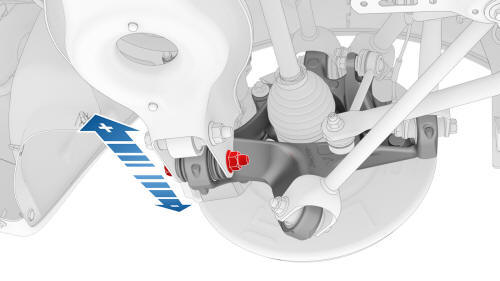

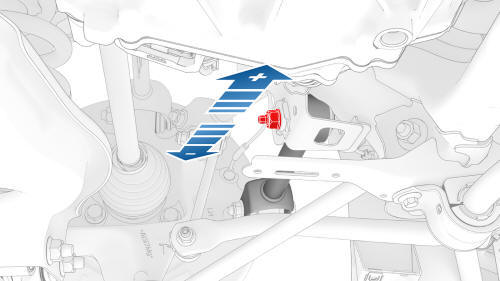

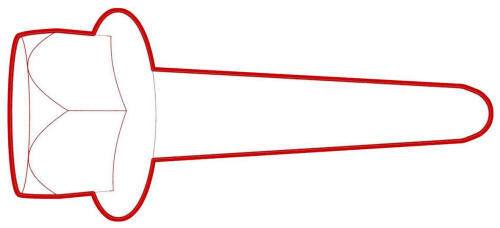

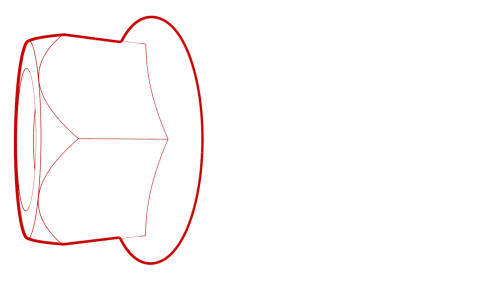

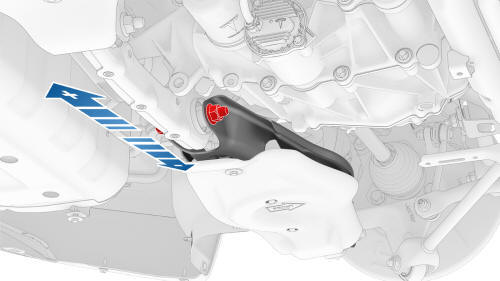

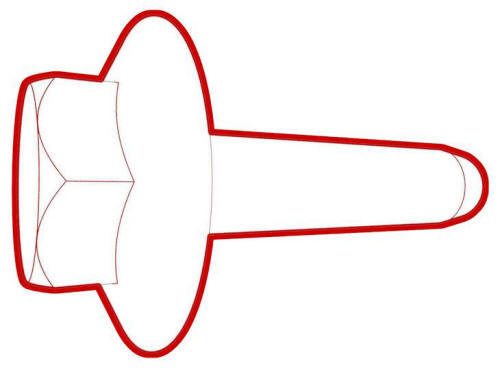

- Loosen the nut on the rear LH toe link to subframe bolt.

- Rotate the rear LH toe link to subframe bolt to adjust the rear LH toe

to 0.20º IN +/- 0.15º (+/- 0.1.º split).

- To add positive toe in, move the link in toward the centerline.

- To add negative toe out, move the link out from the centerline.

- When the rear LH toe is correct, tighten the nut.

.png) Torque 85 Nm

Torque 85 Nm

- Perform step

2 through step

4 for the RH side of the vehicle if necessary.

- Adjust the front camber and caster. See

Adjust Front Camber and Caster.

Adjust Front Camber and Caster

- If the front camber and caster are within specification and do not

require adjustment, adjust the front toe. See

Adjust Front Toe.

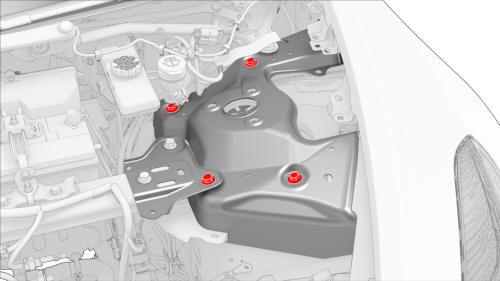

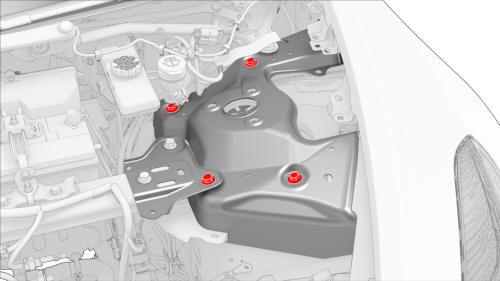

- Remove the cowl screen panel. See

Panel - Cowl Screen (Remove and Replace).

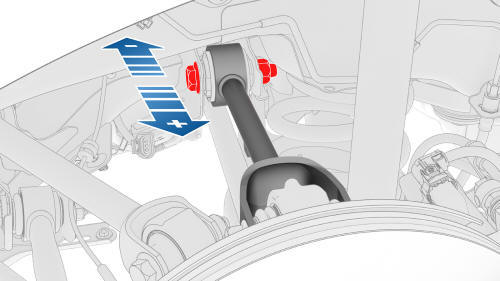

- Mark the location of the LH FUCA mount bolts by drawing a circle around

each.

Note: The circles provide a reference for the adjustment process.

- Slightly loosen, but do not remove, the LH FUCA mount bolts.

- Adjust the front LH camber to -0.50º +/- 0.45º (+/- 0.60º split) and the

LH caster to +5.7º +/- 1.0º (+/- 1.0º split).

- Negative Caster

- Negative Camber

- Positive Caster

- Positive Camber

- Use a pry tool or large screwdriver to pry between the damper mounting

nuts and body openings, so as to move the FUCA mount inside the shock tower.

- Moving the FUCA mount out from the centerline makes positive camber.

- Moving the FUCA mount in toward the centerline makes negative camber.

- Moving the FUCA mount to the rear makes positive caster.

- Moving the FUCA mount to the front makes negative caster.

- When the front LH camber and LH caster are at the correct setting, have

an assistant tighten the FUCA mount bolts to hold the position.

.png) Torque 30 Nm

Torque 30 Nm

- Perform a caster sweep, center and set the steering wheel, and check the

alignment.

- Repeat step

3 through step

8 as necessary.

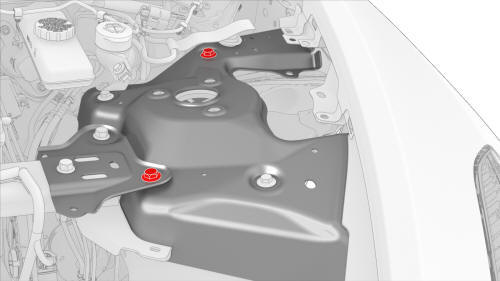

- When the front LH camber and LH caster are correct, tighten the larger

LH FUCA mount bolts.

Torque 62 Nm

Torque 62 Nm

- Tighten the smaller LH FUCA mount bolts.

Torque 35 Nm

Torque 35 Nm

- Perform step

3 through step

11 for the RH side of the vehicle if necessary.

- Adjust the front toe. See

Adjust Front Toe.

Adjust Front Toe

- If the front toe is within specification and does not require adjustment,

complete the alignment. See

Complete the Alignment.

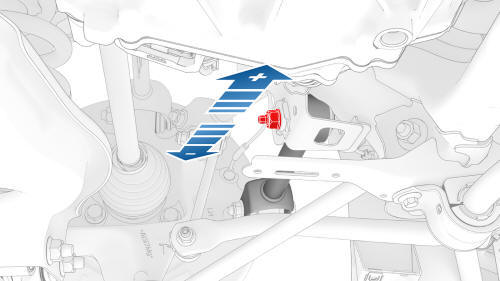

- Loosen the jam nut on the LH inner tie rod.

- Rotate the LH inner tie rod to adjust the front LH toe to 0.05º OUT +/-

0.15º (+/- 0.10º split).

-

To add positive toe in, move the tie rod end in toward the centerline.

-

To add negative toe out, move the tie rod end out from the centerline.

- When the front LH toe is correct, tighten the jam nut on the LH inner

tie rod.

.png) Torque 80 Nm

Torque 80 Nm

- Perform step

2 through step

4 for the RH side of the vehicle if necessary.

- Complete the alignment. See

Complete the Alignment.

Complete the Alignment

- Print the vehicle summary and verify that the alignment parameters are

within specifications.

Note:

Repeat the adjustment for any parameter that is not within specification.

-

Adjust Rear Camber

-

Adjust Rear Toe

-

Adjust Front Camber and Caster

-

Adjust Front Toe

- Install the mid aero shield panel. See

Panel - Aero Shield - Mid (Remove and Replace).

- Lower the alignment rack to a working height and lock.

- Remove the alignment heads from the wheels.

- Remove the brake pedal depressor.

- Install the alignment slip/turn plate pins.

- Lower the alignment rack to the ground.

- Unlatch the driver's door, shift into Park, and remove the steering

wheel bubble leveler.

- Unbuckle the seat belts and remove the ballast bags from the vehicle.

- Remove the seat covers from the seats.

- Connect a laptop with Toolbox 3 to the vehicle.

- In Toolbox, click Actions, type "angle" in the search field, click Play

to the left of "PROC_EPAS3X_X_CLEAR-APPLIED-ANGLE-OFFSET", and then select

Run.

- Click Actions, type "angle" in the search field, click Play to the left

of "TEST_EPAS3P_X_CHECK-APPLIED-ANGLE-OFFSET", and then select Run.

- Disconnect the laptop from the vehicle.

- Remove the wheel chocks.

- Install the cowl screen panel. See

Panel - Cowl Screen (Remove and Replace).

- Remove the vehicle from the alignment rack.

- Perform a test drive and verify vehicle operation.

READ NEXT:

SEE MORE:

Wipers

To perform a single wipe with the windshield

wipers, press and immediately release the

button on the end of the left-hand steering

column lever.

To adjust the continuous wiper settings, touch

the windshield wiper icon located in the

"Cards" area on the touchscreen. The wipe

Remove

Raise and support the vehicle.

Remove the rear underhood apron

Remove the cabin intake duct.

Remove the hood latch cover.

Remove the underhood storage unit.

Remove the front fascia assembly.

Remove the LH front airbag sensor.

Remove the center front airbag sensor.

Remove the RH fr

Torque 106 Nm

Torque 106 Nm

Torque 106 Nm

Torque 106 Nm

.jpg)

.png) Torque Lower Aft

Link to Knuckle Bolt 115Nm

Torque Lower Aft

Link to Knuckle Bolt 115Nm

.png) Torque Lower Aft

Link to Subframe Bolt 115 Nm

Torque Lower Aft

Link to Subframe Bolt 115 Nm

.png) Torque Upper

Aft Link to Subframe Bolt 134 Nm

Torque Upper

Aft Link to Subframe Bolt 134 Nm

.png) Torque 85 Nm

Torque 85 Nm

.png) Torque 30 Nm

Torque 30 Nm

Torque 62 Nm

Torque 62 Nm

Torque 35 Nm

Torque 35 Nm

.png) Torque 80 Nm

Torque 80 Nm