Tesla Model 3: Paint Defect Rectification

Note: This procedure was designed to be performed on flat or near-flat metal body panels with original factory paintwork. Any deviation from these circumstances can alter cutting times, tool speeds, and the ideal amount of pressure to be applied to the body panel. If uncertain about a defect, follow up with a paint correction expert.

Caution:

If performing paint correction on body lines, make the following adjustments:

- Sand paint inclusions only by hand.

- Apply less pressure to the body panel when cutting/polishing.

- Reduce cutting time from 15 seconds to 5 seconds at a time.

- Reduce buffer speed by 40-50%.

- Avoid excessive heat build-up.

- Do not let the compounds dissipate.

Determine Defect Risk Level

Inspect the defect(s) and determine whether they are low or high risk.- If the defect(s) are low risk, continue to the next step.

- If the defect(s) are high risk, escalate the repair to a body shop.

- Less than 1.5 mm diameter on flat or near-flat body panels

- Less than 1.0 mm diameter on or near character lines

- High or low spots

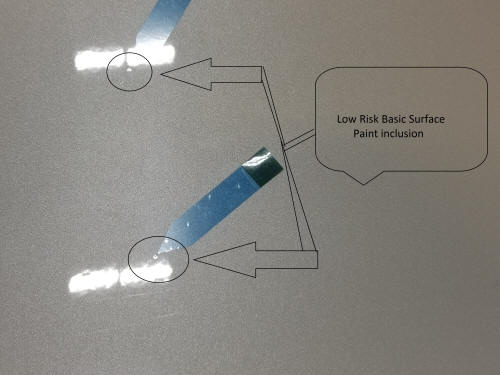

- Basic surface paint inclusions

- Holograms

- Swirls

- Solvent pop

- Overspray

- Light to medium depth scratches

Low risk basic surface paint inclusions

Low risk basic surface paint inclusions

- High Risk Defect Characteristics

- Larger than 2.0 mm diameter on flat or near-flat body panels

- Larger than 1.0 mm diameter on or near character lines

- Off color inclusions

- High or low spots larger than 2.0 mm

High risk off color paint inclusion

High risk defect on character line

READ NEXT:

Remove Dirt Inclusion

Remove Dirt Inclusion

Apply isopropyl alcohol to the general area of the defect, and then wipe

the area with a clean microfiber towel.

While wearing a nitrile glove, run hand over the area around the dirt

inclu

Polish

Polish

Remove the cutting pad from the buffer, and then install a polishing pad on

the buffer.

Apply 4 evenly spaced 20 mm diameter dollops of polishing compound on the

polishing pad.

Set the buffer speed

SEE MORE:

Duct - Cabin Intake (Remove and Replace)

Duct - Cabin Intake (Remove and Replace)

Remove

Remove the rear underhood apron. See

Underhood Apron - Rear (Remove and Replace).

Release the clips (x4) that attach the cabin intake duct to the cowl

screen panel, and then remove the duct from the vehicle.

Install

Installation procedure is the reverse of removal.

Hood (Remove and Install)

Hood (Remove and Install)

Remove

Remove the LH and RH hood gas struts. See Gas Strut - Hood - LH (Remove

and Replace).

Use tape to mark the mounting locations of the LH and RH hood hinges on

the hood.

With an assistant, remove the nuts that attach the hood assembly to the

LH and RH hood hinges.

With

© 2019-2026 Copyright www.tmodel3.com